Nano N2/O2 Generator - The Citra Group

GEN2 – ULTRA PURITY NITROGEN GENERATORS

Nitrogen is used in many commercial and industrial applications to improve the quality of a product or process or as a safety measure to prevent combustion. Liquid or bottled nitrogen delivery and storage can be expensive, unreliable and a safety concern. Nitrogen generators allow users to produce nitrogen in-house simply and inexpensively using an existing compressed air system.

NANO recognises the importance of having a safe, reliable and cost-effective supply of high-purity nitrogen. We have developed the GEN2 nitrogen generator to meet the increasing demand for high quality complete packaged solutions which save energy and time whilst fulfilling the needs of their intended application.

A few of the many industries making the switch to NANO GEN2 nitrogen generators include:

- food (MAP)

- beverage (bottling)

- plastics (PET)

- pharmaceutical (product transfer)

- chemicals (blanketing)

- laser metal cutting (burring reduction)

- fire prevention (eliminating combustion)

- electronics (wave soldering)

Traditional nitrogen generators often require installing and operating an external desiccant dryer. The innovative NANO GEN2 nitrogen generators feature an integrated dryer cartridge which eliminates the need for a pretreatment dryer of any type. The integrated drying system reduces purge loss by approximately 20% and reduces pressure drop by 0.7 bar (10 psi) or more which provides significant energy savings over a traditional generator system.

DOWNLOAD CATALOG

- Guaranteed performance

- reliable performance based on decades of experience with pressure swing adsorption technology

- 100% function and performance tested at our factory

- 2 year warranty

- Rapid return on investment

- significant cost savings over cylinder or liquid supply provides a typical return on investment of less than 24 months

- Easy to install

- the compact design allows installation in spaces too small for twin tower generator systems

- Safe & reliable

- eliminates the safety hazards of transporting and storing pressurised gas cylinders or liquid nitrogen

- Environmentally friendly

- lower air consumption and refined controls provide greater energy efficiency

- reduces carbon footprint by eliminating gas delivery to your facility

- Easy to maintain

- advanced PLC with HMI touchscreen controls simplify operation and require minimal training

- innovative piston valves significantly reduce maintenance schedules and minimise downtime

- Fits any application

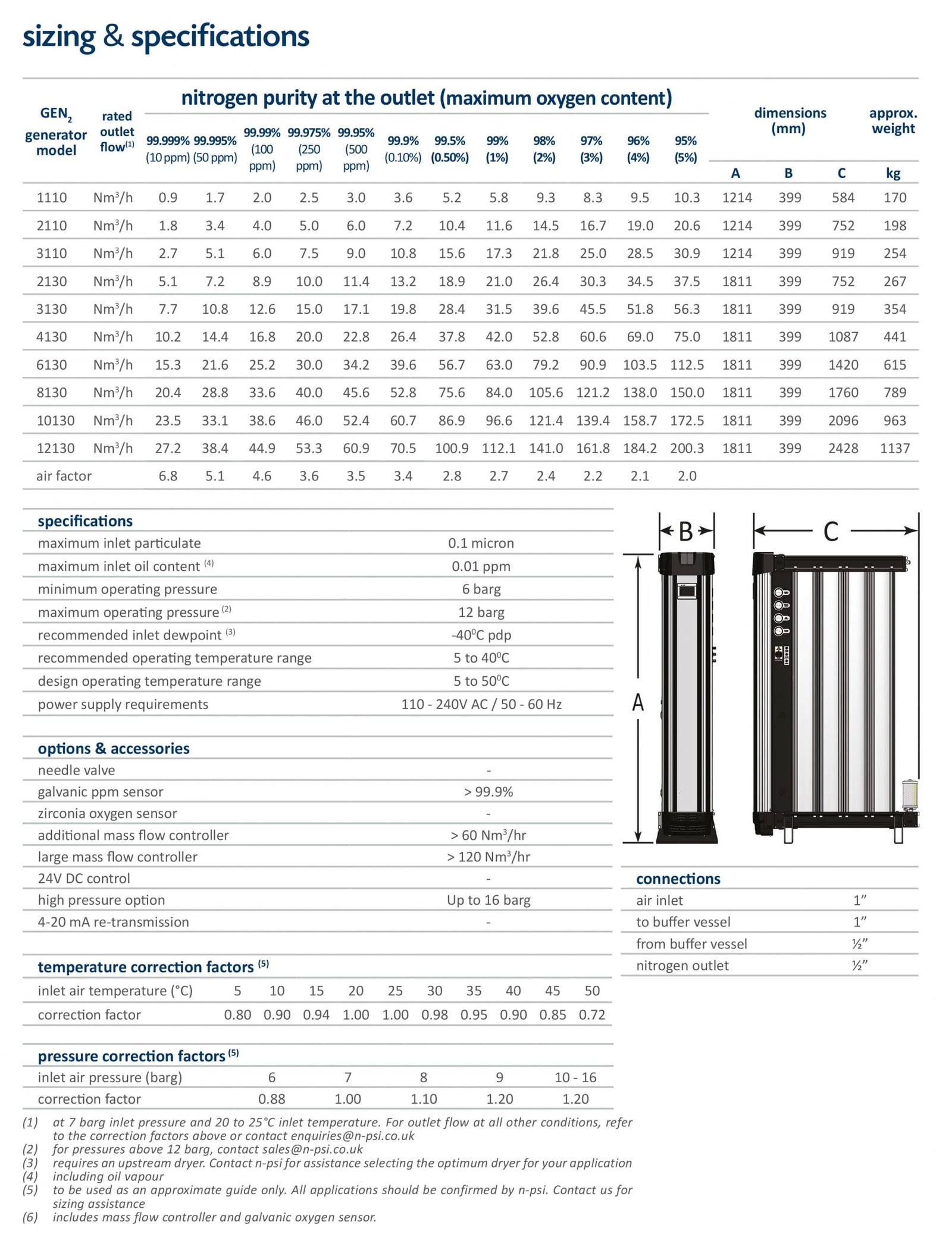

- maximum design operating pressure of 10 barg (16 barg optional)

- available in a wide range of flow rates and purities from 95% - 99.999%

- can handle any power supply from 110 - 240 VAC in 50 - 60 Hz, 24VDC optional

- Design quality

- mass flow controller - ensuring correct set pressure and flow

- integral oxygen analyser - constantly measuring gas purity

- purity guarantee valve - automatically vents off out of specification gas

- remote monitoring - enabling connection to proprietary remote management and generator control systems